When it comes to controlling gas pressure in a laboratory or industrial setting, precision gas pressure regulators are essential. These regulators are designed to provide a constant and accurate gas flow rate, which is crucial for maintaining consistent and reliable results in analytical and manufacturing processes.

There are two main types of precision gas pressure regulators: single-stage and dual-stage. In this blog, we’ll explore the differences between these two types of regulators and when each is most appropriate to use. , we’ll take a closer look at the working principle, main components, applications, industries, advantages, and limitations of single-stage and dual-stage pressure regulators.

Single-Stage Precision Gas Pressure Regulators

Single-stage regulators are the most basic type of gas pressure regulator. The reduction in pressure occurs in a single step, which is why they are called “single-stage” regulators.

Working Principle:

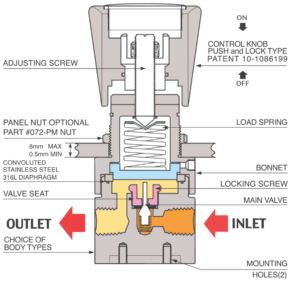

Single-stage pressure regulators work by reducing the high-pressure gas from a cylinder or supply line down to a lower, more usable pressure. The regulator consists of a valve and a diaphragm. The valve controls the gas flow rate, while the diaphragm controls the pressure.

When the gas pressure is higher than the desired output pressure, the diaphragm is pushed upwards, which closes the valve and reduces the gas flow rate. Conversely, when the gas pressure is lower than the desired output pressure, the diaphragm is pushed downwards, which opens the valve and increases the gas flow rate.

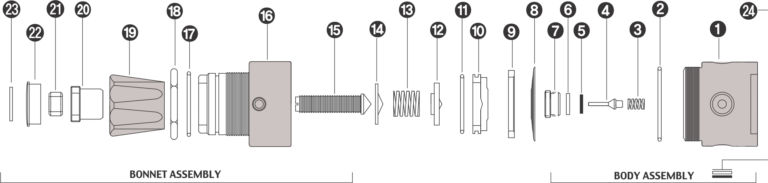

Main Components:

The main components of a single-stage pressure regulator include a body, diaphragm, valve, pressure gauge, and inlet and outlet connections. The body of the regulator houses the diaphragm and valve, while the pressure gauge indicates the output pressure.

Applications and Industries:

Single-stage pressure regulators are commonly used in a variety of applications, including gas welding and cutting, laboratory research, chemical processing, and semiconductor manufacturing. They are also used in industries such as aerospace, automotive, energy, and medical.

Advantages:

Single-stage pressure regulators are relatively inexpensive and simple to use. They are suitable for applications where a consistent gas flow rate is required and are effective at reducing high-pressure gas down to a lower, more usable pressure.

Limitations:

Single-stage pressure regulators may not be suitable for applications where the gas supply pressure is unstable or where precise gas flow control is necessary. They are also not recommended for applications that require very low or very high output pressures.

Dual-Stage Precision Gas Pressure Regulators

Dual-stage regulators are more complex than single-stage regulators and provide greater precision in gas pressure control.

Working Principle:

Dual-stage pressure regulators work by reducing the high-pressure gas from a cylinder or supply line down to a lower, more usable pressure in two stages. The first stage reduces the gas pressure from the source to an intermediate pressure, while the second stage further reduces the gas pressure to the desired output pressure.

The first stage of the regulator reduces the high-pressure gas to an intermediate pressure and maintains a relatively constant output pressure, regardless of changes in the supply pressure. The second stage further reduces the gas pressure and provides fine control over the output pressure.

Main Components:

The main components of a dual-stage pressure regulator include a body, diaphragms, valves, pressure gauges, and inlet and outlet connections. The body of the regulator houses the diaphragms and valves, while the pressure gauges indicate the intermediate and output pressures.

Applications and Industries:

Dual-stage pressure regulators are commonly used in applications where precise gas flow control is necessary, such as in gas chromatography, analyzers, pharmaceutical manufacturing, and semiconductor manufacturing. They are also used in industries such as aerospace, automotive, energy, and medical.

Advantages:

Dual-stage pressure regulators offer greater precision and stability in gas pressure control than single-stage regulators. They are more suitable for applications where the gas supply pressure is unstable or where precise gas flow control is necessary. They also provide a more stable and accurate gas flow rate, which is important for critical applications.

Limitations:

Dual-stage pressure regulators are more expensive than single-stage regulators and may be more complex to operate. They may also not be suitable for applications where a consistent gas flow rate is required, as they are designed to provide precise control over the gas flow rate.

Conclusion:

Single-stage pressure regulators are a popular and cost-effective option for controlling gas pressure in a variety of applications and industries. They work by reducing high-pressure gas down to a lower, more usable pressure, and consist of a valve and diaphragm. While they are suitable for many applications, they may not be appropriate for those requiring precise gas flow control or very low or very high output pressures.

Dual-stage pressure regulators are a popular option for controlling gas pressure in a variety of applications and industries that require precise gas flow control. They work by reducing the high-pressure gas down to a lower, more usable pressure in two stages and consist of multiple diaphragms and valves. While they are more expensive and complex to operate than single-stage regulators, they offer greater precision and stability in gas pressure control.

Both single-stage and dual-stage precision gas pressure regulators have their advantages and disadvantages, and the choice of which to use depends on the specific application. Single-stage regulators are suitable for applications where consistent gas flow is required, while dual-stage regulators are preferred for applications where precise gas flow control is necessary.

It is essential to choose the right precision gas pressure regulator for your specific application to ensure accurate and reliable gas flow control. Consult with a gas pressure regulator expert to help determine which type of regulator is best suited for your application.